Liquid Depth Gauge

Overview

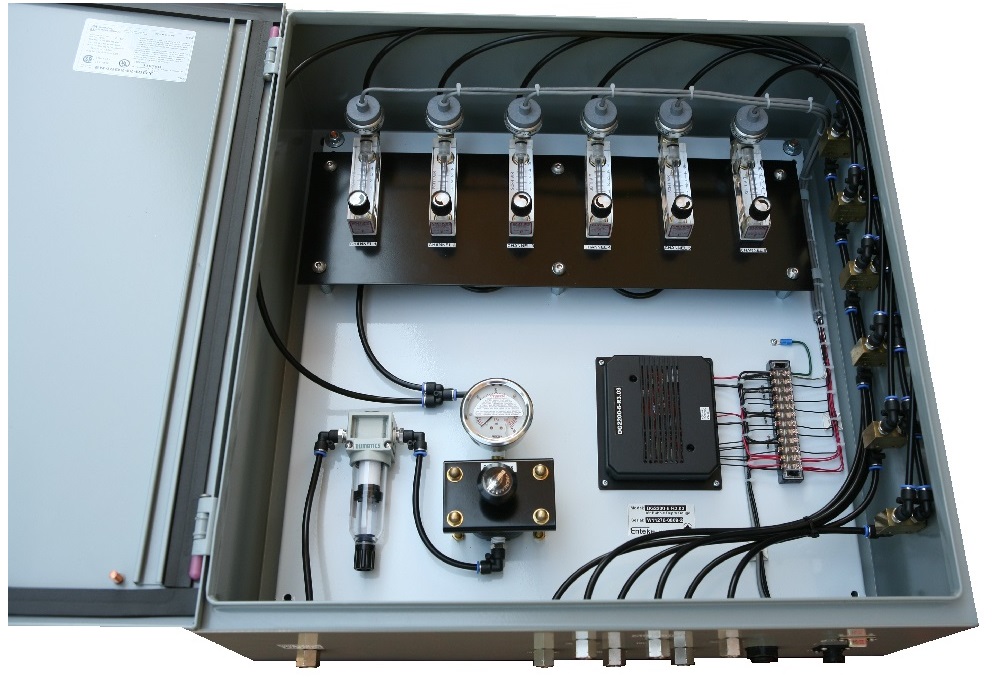

The DG2200 Air Bubble Depth Gauge is designed to provide accurate depth measurements without the need for costly sensors to be located underwater.This drastically increases sensor life and reduces sensor maintenance requirements. The DG2200 is available in depth ranges from only a few meters up to over 100 meters. An integral electronic control unit (ECU) collects and processes sensor data, and can communicate with external software via serial or Ethernet connection. Configuration is achieved through a user-friendly web interface. The DG2200 is available in both single and multi channel configurations, and requires only a basic air supply and control power. All components are housed in a NEMA 4 rated enclosure and includes a convenient purge function for each channel.

Connections

Both Ethernet and RS232 (serial) connections are provided to communicate with the user’s software or systems.

Air Supply

A clean air supply (providing minimal air flow < 1 CFM) is required. This should be connected to the inlet port fitting on the bottom of the gauge enclosure.The required minimum and maximum PSI of the air supply depends on the specific depth range of the gauge.

Sensor Ports (Outlets)

A suitable hose or pipe should be installed between the DG2200 gauge and the location to be measured. A separate line is required for each channel, or location, to be measured. In some cases it is not practical to terminate the sensor line at the desired depth; however, in such cases, the readings can be scaled to achieve the desired depth measurements. In turbulent applications, the end of the sensing line can be installed into a stilling well to minimize the effects of the turbulence. In applications with solid material in the liquid being measured, a screen can be installed at the end of the sensor line. A purge function is built into the DG2200 in order to help avoid build-up of the solid material on the screen.

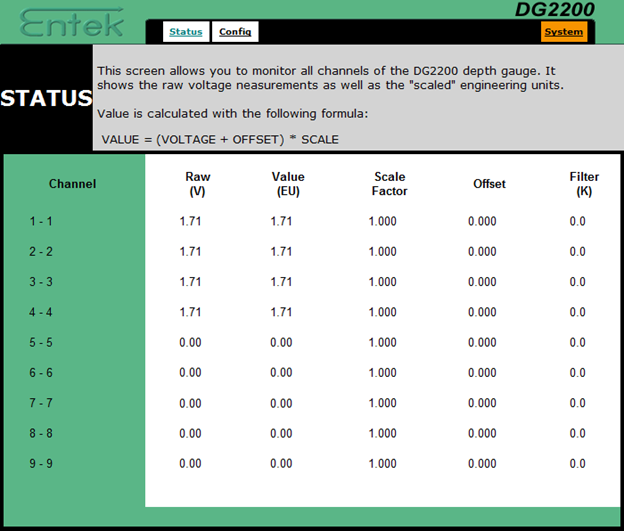

Web Interface (HTTP)

The Web Interface allows the user to monitor the DG2200 and configure the device to the required settings.

Scaling and filter settings may be set in the DG2200, allowing the direct output of measurements in the desired engineering units.

Range

The DG2200 is available in a variety of depth ranges. It is recommended to specify a maximum range as close as possible to the desired maximum depth; however, the maximum range of the DG2200 must exceed the maximum depth in order to ensure reliable and accurate performance. Multi-channel units are normally supplied with the same maximum depth for all channels (see chart below).

NOTE: For multi-channel units with varying maximum depths, please consult Entek.